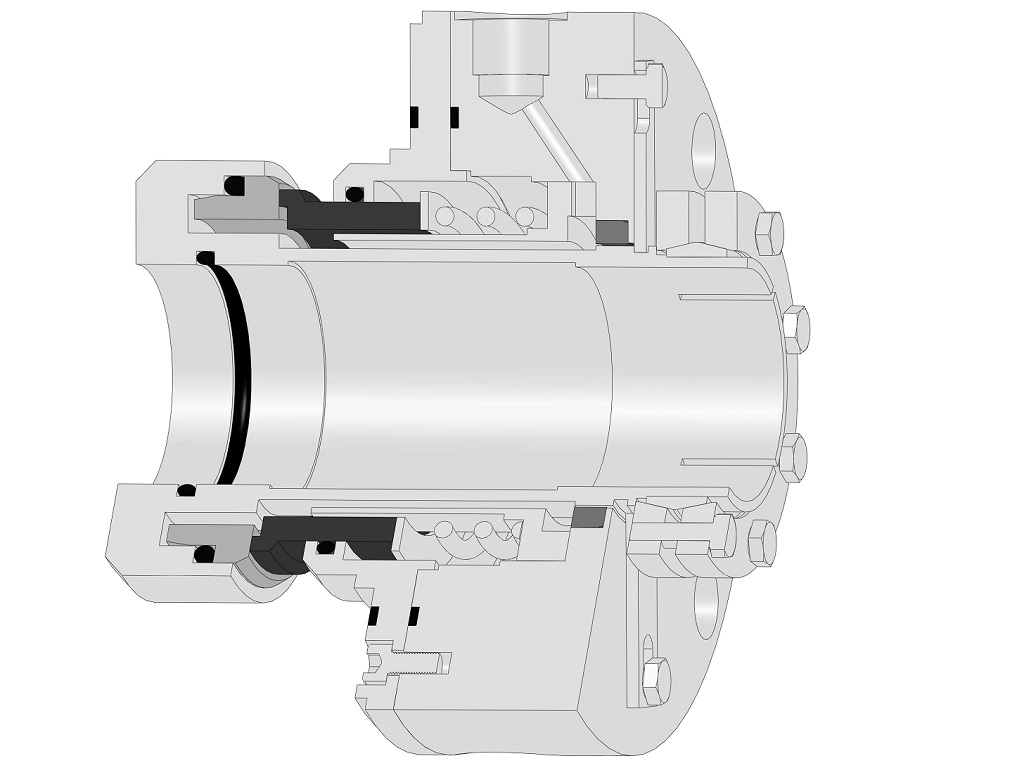

Slurry Seal PM71

Features:

- Single

- Balanced

- Cartridge unit

- Stationary spring

- Single Spring

- Independent direction of rotation

Typical Applications:

Commonly used in rotating equipment for crystallizing and particle-laden media applications across industries including mining/metallurgy, water treatment, power plant desulfurization, and paper/pulp production.

Mediums:

Suitable for crystallizing and particulate-laden media, such as sulfur.

Performance Capabilities:

Pressure: 0~ 5 MPa

Temperature: -40 ~260°C

Linear Speed: ≤25 m/s

Material Selection:

Metallic Components: 1Cr13、304、316L、2507、TA2

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC

Elastomer Options: FKM, FFKM, EPDM, NBR

-

Product Description:

Designed to API 682 standards for rotating equipment handling crystallizing & particulate-laden process media. It is rated for a pressure of up to 5 MPa. It includes shaft sleeve, rotating ring, stationary ring, auxiliary seals, flexible elements, seal gland and drive mechanism.

Technical Features:

1.High-strength seal materials for optimal performance.

2.Balanced design with precisely calculated face pressure ratio to reduce face load and minimize heat generation.

3.Single spring design with corrosion resistance, high torsional strength, and capability to withstand significant axial and radial forces.

4.The fixed throttle bushing design maintains seal chamber pressure and reduces seal leakage.

5.Large-cross-section sealing rings maintain floatability while enhancing sealing performance.

6.The highly reliable drive design effectively prevents slippage even on high-hardness shafts.

Solution Selection:

Plan 32 flush scheme is commonly used to provide lubrication and cooling for the seal.