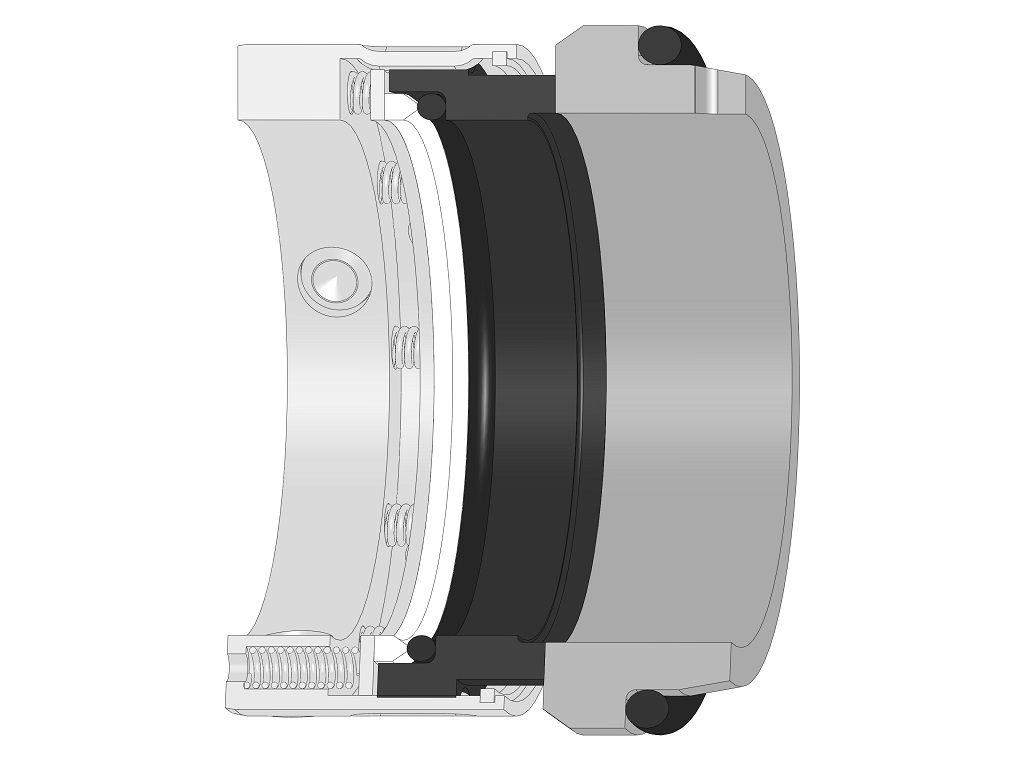

Multiple Spring Mechanical Seal-PM1

Features:

- Single seal

- Unbalanced

- Independent of direction of rotation

Typical Applications:

Designed for clean, low-corrosion chemicals and other low-pressure rotating equipment applications.

- Process industry

- Chemical industry

- Pulp and paper industry

- Water and waste water technology

- Shipbuilding

- Lube oils

- Low solids content media

- Water / sewage water pumps

- Chemical standard pumps

- Vertical screw pumps

- Gear wheel feed pumps

- Multistage pumps (drive side)

Mediums:

Suitable for water, general chemical solutions, weak acids/alkalis/salts, refrigerants, and mildly abrasive fluids.

Performance Capabilities:

Pressure: 0~ 2.5 MPa

Temperature: -50 ~220°C

Linear Speed: ≤20 m/s

Material Selection:

Metallic Components: 1Cr13、304、316L、2205、2507

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC、Graphite

Elastomer Options: FKM, FFKM, EPDM, NBR , OMNISEAL

-

Product Description:

Designed in accordance with DIN24960、EN12756. It is rated for a pressure of up to 2.5 MPa. It includes rotating ring, stationary ring, auxiliary seals, compensation components,spring retainer.

Technical Features:

1.Single-end spring mechanical seal.

2.High-strength,High-performance seal materials for optimal performance

3.Unbalanced design with rotating multi-spring configuration ensures even spring pressure, maintaining face contact for effective sealing performance.

4.Large-cross-section sealing rings maintain floatability while enhancing sealing performance.

5. Reliable drive system with tool-free installation.

6.Versatile configurations and material pairings for wide-ranging applications.

7.Product design complies with DIN 24960 and EN 12756 standards.

This product can be an alternative to similar products such as EagleBurgmann M7N.