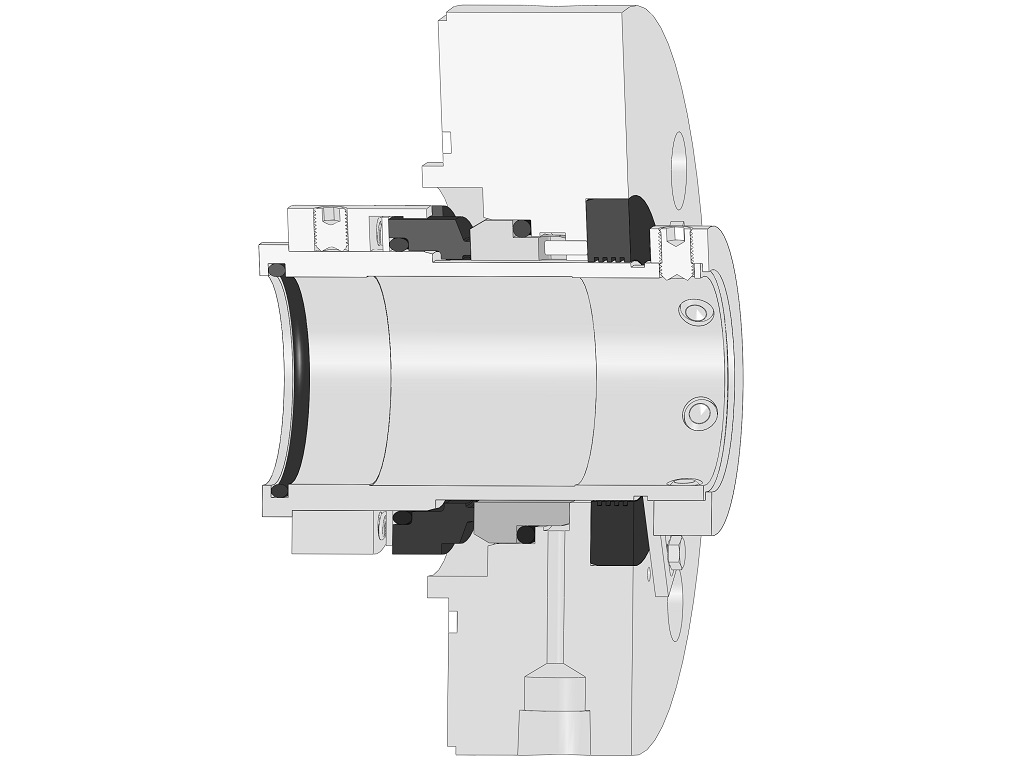

Multiple Spring Mechanical Seals-APM41

Features

- API 682 Category 2 and 3, Type A, Arrangement 1 seal

- Single seal

- Balanced

- Cartridge unit

- Bi-directional design

- Rotating multiple springs

Typical Applications:

Designed for rotating equipment in oil & gas, petrochemical, chemical and power industries handling fluid services.

Mediums:

Suitable for petroleum, chemical solutions, weak acids/alkalies, salts, refrigerants and fluids with low solids content.

Performance Capabilities:

Pressure: 0~ 4.5MPa

Temperature: -40 ~260°C

Linear Speed: ≤25 m/s

Material Selection:

Metallic Components:304、316L、2205、2507

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC、Graphite

Elastomer Options: FKM, FFKM, EPDM, NBR , OMNISEAL

-

Product Description:

Designed in accordance with API682. It is rated for a pressure of up to 4.5 MPa. It includes sleeve,rotating ring, stationary ring, auxiliary seals, compensation components,seal glad,throttle bushing,drive components.

Technical Features:

1.High-strength,High-performance seal materials for optimal performance.

2.Balanced design with precisely calculated face pressure ratio to reduce face load and minimize heat generation.

3.Fixed throttle bushing design maintains seal chamber pressure and minimizes leakage.

4.Large-cross-section sealing rings maintain floatability while enhancing sealing performance.

5.Highly reliable drive design effectively prevents slippage.

This product can be an alternative to similar products such as EagleBurgmann H75VN.

Solution Selection:

Standard Flush Plans & Applications:

• General duty: Plan 11/12/13

• High-temperature: Plan 21

• Enhanced cooling: Plan 23 (with forced circulation)

• Solids/viscous media: Plan 32 (external flush)