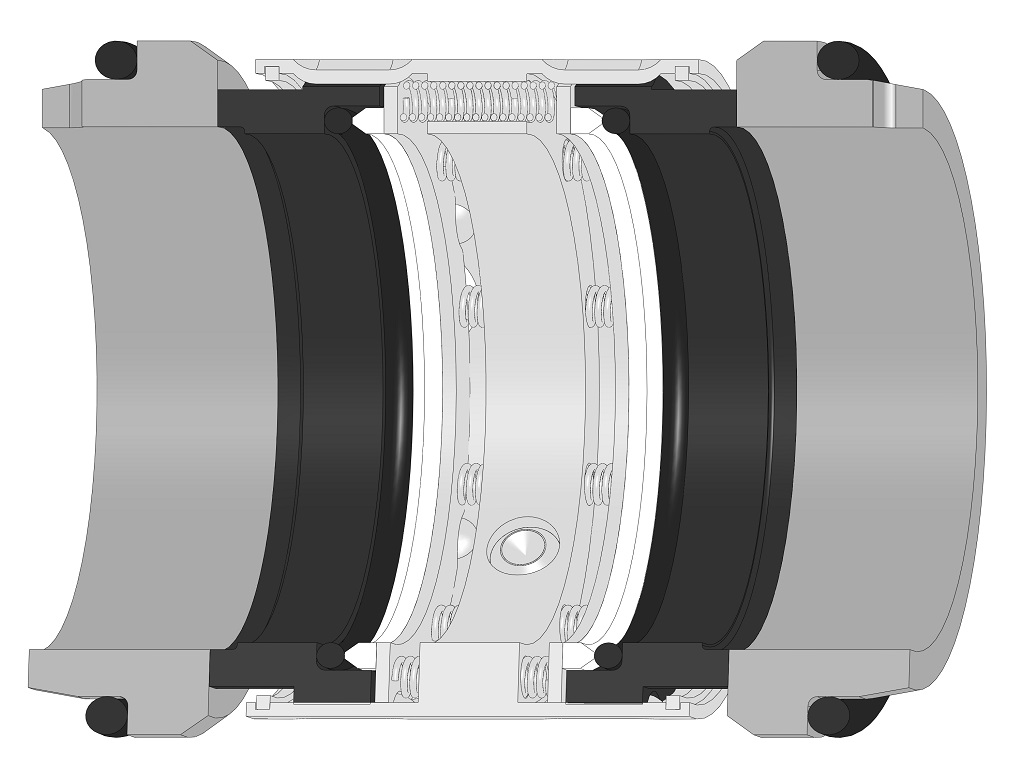

Multiple Spring Mechanical Seals-PM13

Features

- Dual seal

- Unbalanced

- Rotating multiple springs

- Independent of direction of rotation

Typical Applications:

Designed for rotating shaft equipment handling toxic, hazardous, flammable, or explosive media that cannot form a liquid film.

- Chemical industry

- Process industry

- Pulp and paper industry

- Chemical standard pumps

Mediums:

Suitable for petroleum, chemical solutions, weak acids, alkalis, salts, refrigerants, and media containing low solids content.

- Low solids content and low abrasive media

- Toxic and hazardous media

- Media with poor lubrication properties

- Adhesives

Performance Capabilities:

Pressure: 0~ 2.5 MPa

Temperature: -50 ~220°C

Linear Speed: ≤20 m/s

Material Selection:

Metallic Components: 1Cr13、304、316L、2205、2507

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC、Graphite

Elastomer Options: FKM, FFKM, EPDM, NBR , OMNISEAL

-

Technical Features:

1.Dual multiple spring mechanical seal.

2.High-strength,High-performance seal materials for optimal performance.

3.Unbalanced design with multi-spring configuration ensures even spring pressure, maintaining face contact for effective sealing performance.

4.Large-cross-section sealing rings maintain floatability while enhancing sealing performance.

5. Reliable drive system with easy installation.

6.Product design complies with DIN 24960 and EN 12756 standards.

This product can be an alternative to similar products such as EagleBurgmann M74-D.