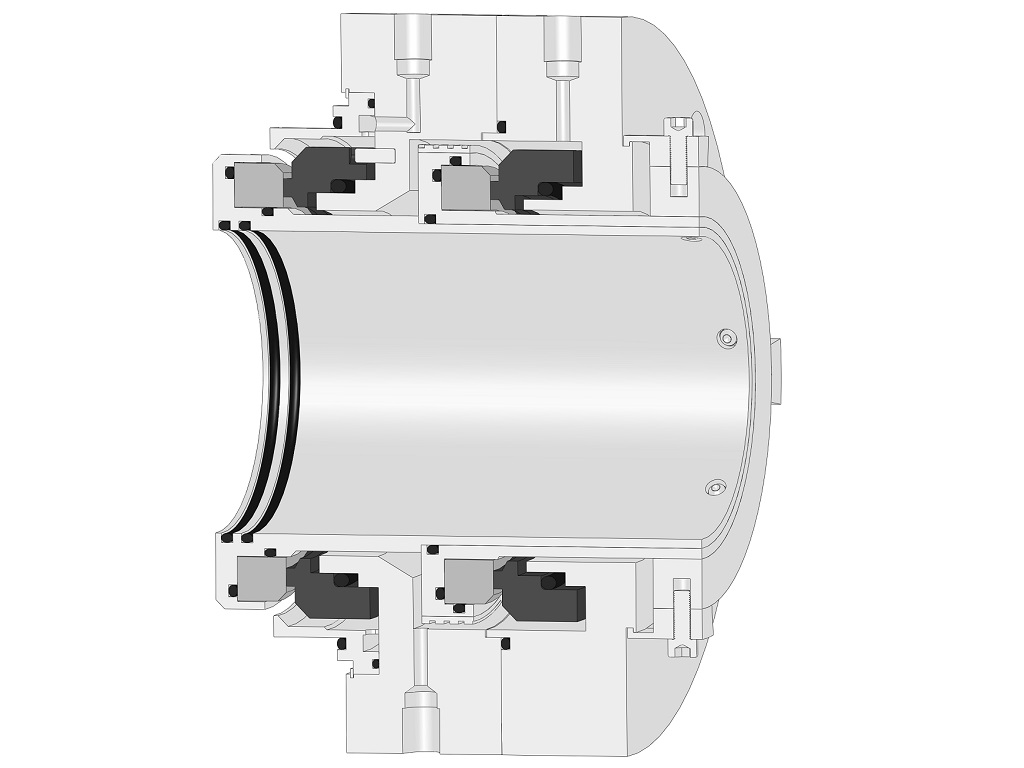

Multiple Spring Mechanical Seals-APM82

Features

- API 682 Category 2 and 3, Type A, Arrangement 2 seal

- Dual seal in face-to-back arrangement

- Balanced

- Cartridge unit

- Rotating multiple springs

Typical Applications:

Engineered for hydrocarbon service and high-pressure applications with flammable, explosive, or highly toxic fluids.

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- CCUS

- Alternative fuels production

- Light volatile hydrocarbons

- LPG plants

- API 610 / ISO 13709 pumps

- Process pumps

Mediums:

Suitable for petroleum, chemical solutions, weak acids/alkalies, salts, refrigerants and fluids with low solids content.

Performance Capabilities:

Pressure: 0~ 4.5MPa

Temperature: -40 ~260°C

Linear Speed: ≤25 m/s

Material Selection:

Metallic Components:304、316L、2205、2507

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC、Graphite

Elastomer Options: FKM, FFKM, EPDM, NBR , OMNISEAL

This product can be an alternative to similar products such as EagleBurgmann LL9DTUU.

-

Technical Features:

1.High-strength,High-performance seal materials for optimal performance.

2.Balanced design with precisely calculated face pressure ratio to reduce face load and minimize heat generation.

3.Multiple-spring design: compact size, even spring load, ensures optimal face contact for reliable sealing.

4.Built-in flush circulation system – enhances fluid flow efficiency and optimizes seal operating conditions.

5.Large-cross-section sealing rings maintain floatability while enhancing sealing performance.

6.Highly reliable drive design effectively prevents slippage.

Solution Selection:

A barrier fluid system or buffer fluid system is required to provide lubrication and cooling for the seal operation. The barrier fluid pressure is generally at atmospheric pressure. The front seal can select Plan 11, 21, or 32 flushing schemes based on field conditions. The outer seal can adopt Plan 52 or 55 flushing schemes.