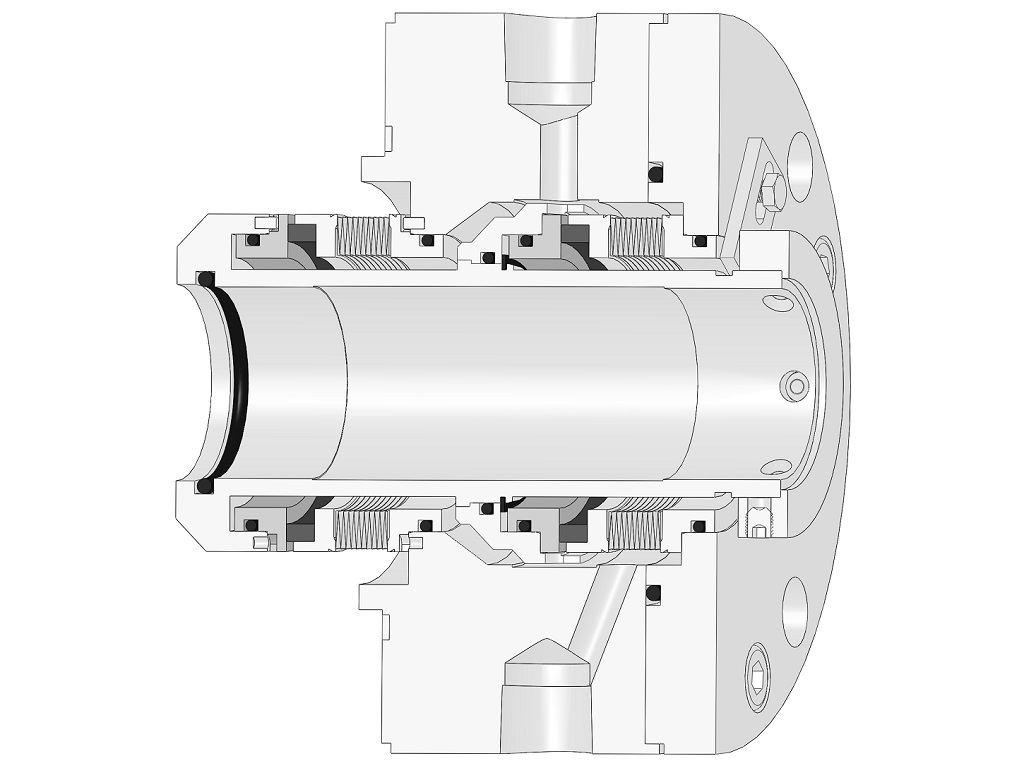

Metal Bellows Seal-BPB83

Features:

- APl 682 Category 2 and 3, Type B, Arrangement 2 and 3 seal

- Dual seal in face-to-back arrangement

- Balanced

- Cartridge unit

- Stationary metal bellow.

Typical Applications:

Engineered for high-risk fluid services exceeding 180°C.

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- LPG plants

- API 610 / 1S0 13709 pumps

- Process pumps

Mediums:

Suitable for petroleum, chemical solutions, weak acids/alkalies, salts, refrigerants and fluids with low solids content.

Performance Capabilities:

Pressure: 0~ 3.5MPa

Temperature: -200 ~400°C

Linear Speed: ≤50 m/s

Material Selection:

Metallic Components:304、316L、2205、2507

Spring: 316L, Hastelloy C-276,TA2、Inconel 718

Seal Rings: SSiC , WC、Graphite

Elastomer Options: FKM、FFKM、EPDM、NBR、OMNISEAL

This product can be an alternative to similar products such as Eagel Burgmann LY9DETT.

-

Product Description:

Designed in accordance with API682,compliant with API 610 seal chamber dimensions. It is rated for a pressure of up to 3.5 MPa. It includes shaft sleeve,rotating ring, stationary ring,auxiliary seals, flexible elements,seal glad,drive components.

Technical Features:

1.High-strength,High-performance seal materials for optimal performance.

2.Bellows design minimizes face load fluctuations, ensuring stable and reliable sealing performance.

3.Built-in flush circulation system – enhances fluid flow efficiency and optimizes seal operating conditions.

4.Large-cross-section sealing rings maintain floatability while enhancing sealing performance.

5.Compact radial design – fits existing seal chambers without modification.

6.Highly reliable drive design effectively prevents slippage.

Solution Selection:

Primary seal options: Plan 02 or Plan 32 based on process conditions and media temperature. Secondary seal defaults to Plan 52 with Plan 54 as optional. Tertiary seal configurable with Plan 62 when required.