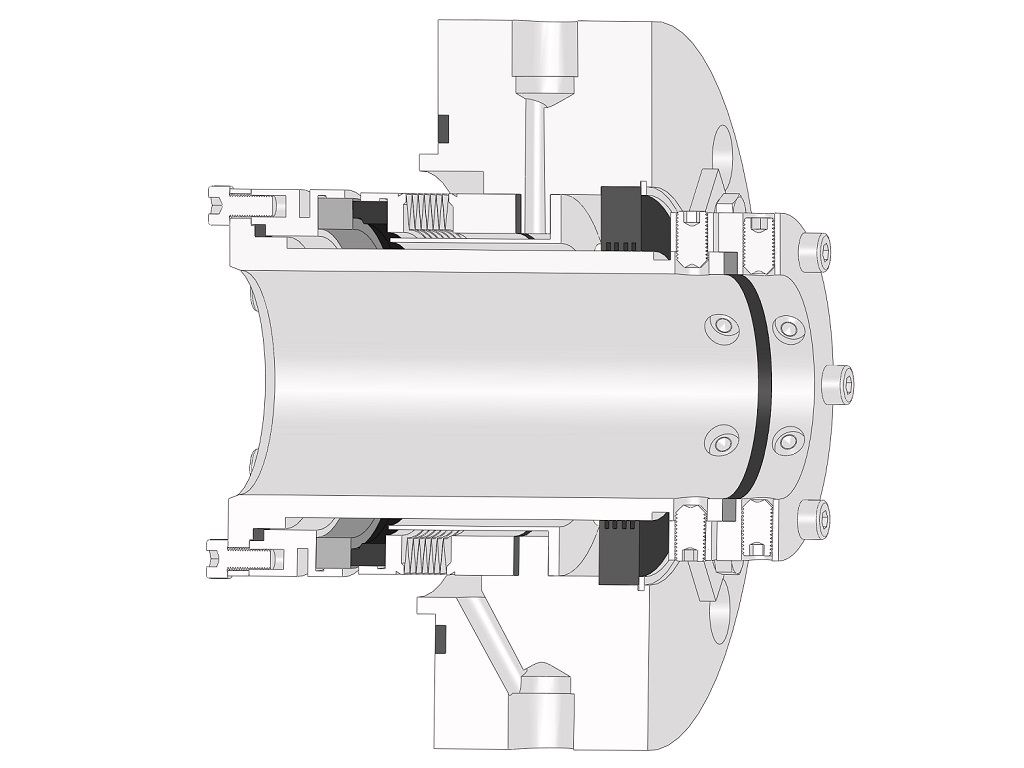

Metal Bellows Seal-BPB61

Features

- API 682 Category 2 and 3, Type C, Arrangement 1 seal

- Single Seal

- Balanced

- Cartridge unit

- Stationary metal bellows

Typical Applications:

For rotating equipment in oil/petrochemical/chemical industries handling heavy oil, hydrocarbons, and high-temperature fluids under slight vacuum, high-speed, and high-temperature conditions.

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- LPG plants

- API 610 / ISO 13709 pumps

- Process pumps

Mediums:

Suitable for petroleum, chemical solutions, weak acids/alkalies, salts, refrigerants and fluids with low solids content.

Performance Capabilities:

Pressure: 0~3.5MPa

Temperature: -200 ~400°C

Linear Speed: ≤50 m/s

Material Selection:

Metallic Components:304、316L、2205、2507

Spring: 316L, Hastelloy C-276,TA2、Inconel 718

Seal Rings: SSiC 、 WC、Graphite

Elastomer Options: Graphite

This product can be an alternative to similar products such as Eagel Burgmann LY9TC.

-

Product Description:

Designed in accordance with API682,compliant with API 610 seal chamber dimensions. It is rated for a pressure of up to 3.5 MPa. It includes sleeve,rotating ring, stationary ring, auxiliary seals, flexible elements,seal glad,throttle bushing,drive components.

Technical Features:

1.High-strength,High-performance seal materials for optimal performance.

2.Balanced design with precisely calculated face pressure ratio to reduce face load and minimize heat generation.

3.Bellows design – minimizes face load fluctuations for stable, reliable sealing performance.

4.Flexible graphite sealing rings – superior temperature resistance for extreme service conditions.

5.Fixed throttle bushing design – maintains seal chamber pressure & minimizes leakage.

6.Highly reliable drive design effectively prevents slippage.

Solution Selection:

Standard Flush Plans & Applications:

- Standard: Plan 21 / Plan 32

- Barrier seal: Optional Plan 62 (pressurized barrier system)