Mechanical Seal For Compressor and Blower-CHM81

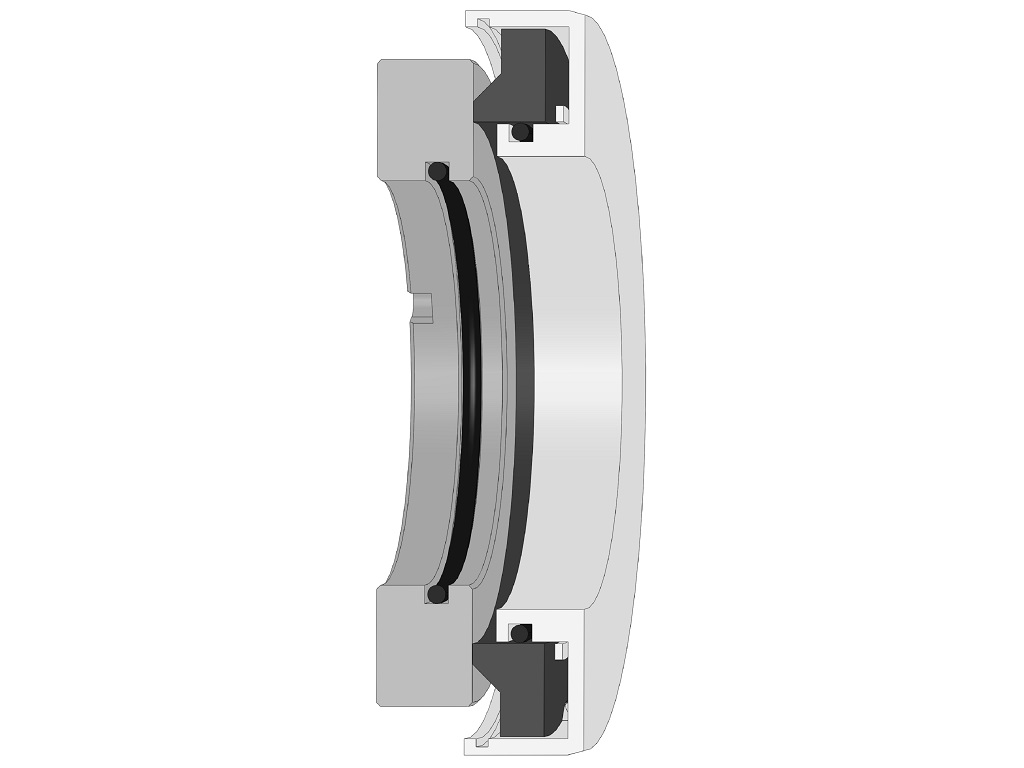

Product Description:

Designed in accordance with API 682 as a replacement for high-speed mechanical seals and carbon ring seals. It is rated for a pressure of up to 1.0MPa. It includes rotating ring, stationary ring, auxiliary seals, flexible elements.

Typical Applications:

Designed for low-pressure gas handling equipment – centrifugal/Roots/axial fans, compressors, dryers, and high-speed bearing housings handling vapors, oil mist, or wet gases.

Widely used in metallurgy, chemical, cement, textile, mining, marine engineering, Food Engineering, environmental and new energy industries. FDA-compliant materials available for pharmaceutical/food-grade steam/gas transfer.Offers longer service life and lower leakage rates compared to floating ring and labyrinth seals.

Mediums:

Various low-pressure gas and steam process media.

Performance Capabilities:

Pressure: ≤1 MPa(Operates in low-vacuum environments without support systems.)

Temperature: -200 ~260°C

Linear Speed: ≤55 m/s

Material Selection:

Metallic Components: 1Cr13、304、316L、2205、2507、Hastelloy “C”

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC,Graphite

Elastomer Options: FKM, FFKM, NBR , EPDM

-

Technical Features:

1.Semi-contact floating face design.

2.High-performance, low-friction sealing materials for optimal seal performance.

3.Combining contact and non-contact designs for extended service life.

4.Utilizing medium pressure and elastic element force to achieve end-face contact and prevent leakage.

5.Independent direction of rotation.

6.Simple structure, easy installation, and convenient maintenance.

Solution Selection:

For liquid transfer equipment, Plan 11, 21, 23, or 32 flush plans are available.

For gas-handling equipment, Plan 74 or a steam-quench system can be selected.