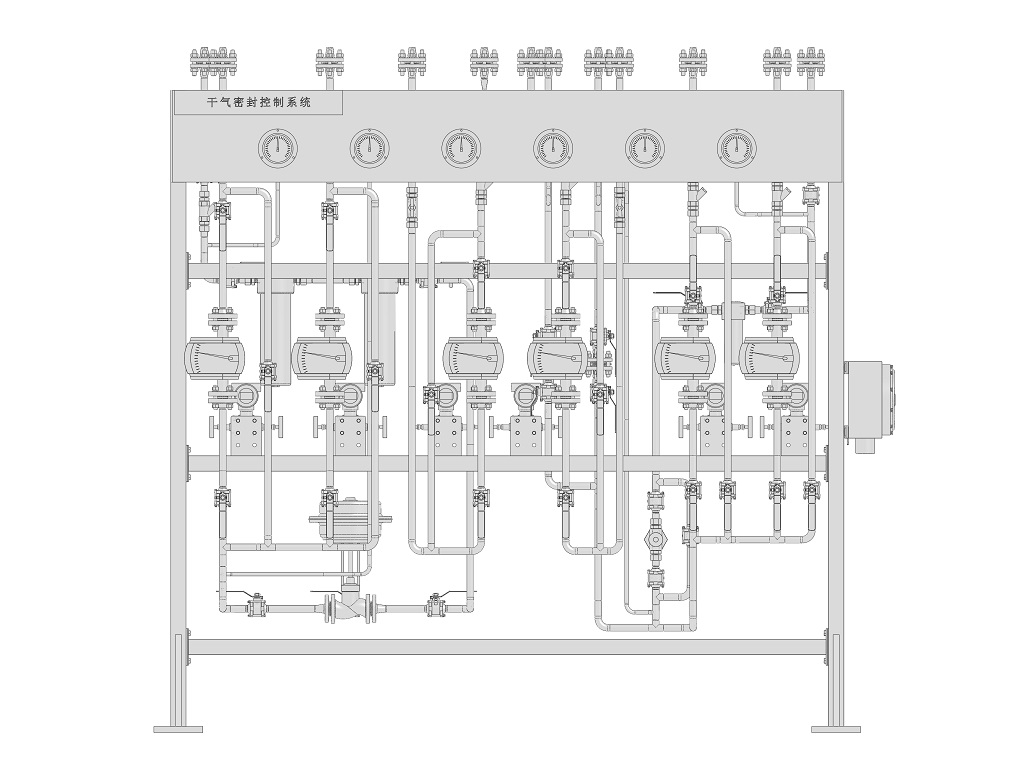

GCS822-II Centrifugal Compressor Tendam Dry Gas Seal Support System

Product Description

1.Applied for Tandem Dry Gas Seal.

2.Provides dry, clean gas for seal.

3.Regulates and analyzes the pressure, flow, and temperature of the seal gas during operation.

4.Reflects the working status of seal, also provides alarm and interlock functions.

5.Including primary seal gas supply module, primary vent gas module and separation gas supply module.

6.Configures booster, heater, separator, gas source auto switch, etc. in accordance withdifferent cases.

Configuration and Function

Primary Seal gas and Secondary Seal Gas supply module

Filter Unite:Remove the particles and a small amount of liquid from seal gas

Differential Pressure Control Unit:Control the pressure of seal gas

Flow Control Unit:Control the flow of seal gas

Separation Gas Supply Module

Filter Unit:Remove the particles and a small amount of liquid from seal gas

Pressure Control Unit: Stabilize gas supply pressure

Flow Control Unit:Control gas supply flow

Vent gas module

Pressure Monitor Unit: Monitor vent gas pressure,reflect the working status of seal

Flow Monitor Unit:Monitor vent gas flow,reflect the working status of seal

-

Designed in accordance with API 692 standards, this system is used in conjunction with dry gas seals to provide clean, dry gas, ensuring stable and reliable seal performance. The system includes tubing connectors, differential pressure transmitters, ball valves, check valves, filters, pressure gauges,pressure transmitter,flow meters, and explosion-proof junction boxes.

Technical Features:

- This system regulates, controls, and monitors dry gas seal (DGS) operating parameters, delivering dry, clean gas to ensure stable and reliable seal performance.

2.This system enables a single gas source to supply multiple seals, ensuring efficient and reliable operation.It consists of primary seal gas supply process,secondary seal gas supply process,isolation gas supply process,vent gas management process.

3.The primary seal gas supply system features a filtration unit, pressure control unit, and flow monitoring unit. External gas enters the system, first passing through the filtration unit to remove particulate contaminants. The gas is then precisely regulated to the required primary seal gas pressure before final flow measurement and delivery into the seal gas chamber. This primary seal gas barrier effectively prevents contaminated process gas from migrating into the dry gas seal area.

4.The system connects to the equipment cavity and monitors the differential pressure (DP) between process gas and primary seal gas using high-accuracy DP transmitters.

5.The secondary seal gas supply process includes filtration unit, pressure control unit, and flow monitoring unit. During operation, external gas enters the system and is first regulated to the required seal gas pressure by the pressure control unit. It then passes through the filtration unit to remove particulate contaminants. The gas is precisely regulated to the required secondary seal gas pressure, then monitored for flow before entering the seal chamber.

6.The isolation gas supply system consists of a filtration unit and a pressure control unit. When external gas enters the system, it first passes through the filtration unit to remove particulate contaminants.The gas is precisely regulated to the required isolation gas pressure, then flows through an orifice plate before entering the seal cavity.

7.The vent gas system consists of a pressure monitoring unit and flow monitoring unit. During operation, leakage gas exits through the seal vent port, first passing through the pressure monitoring unit for real-time pressure measurement, then through the flow monitoring unit before being safely discharged to a flare system or closed collection system.

8.Custom-configured to your operational needs.