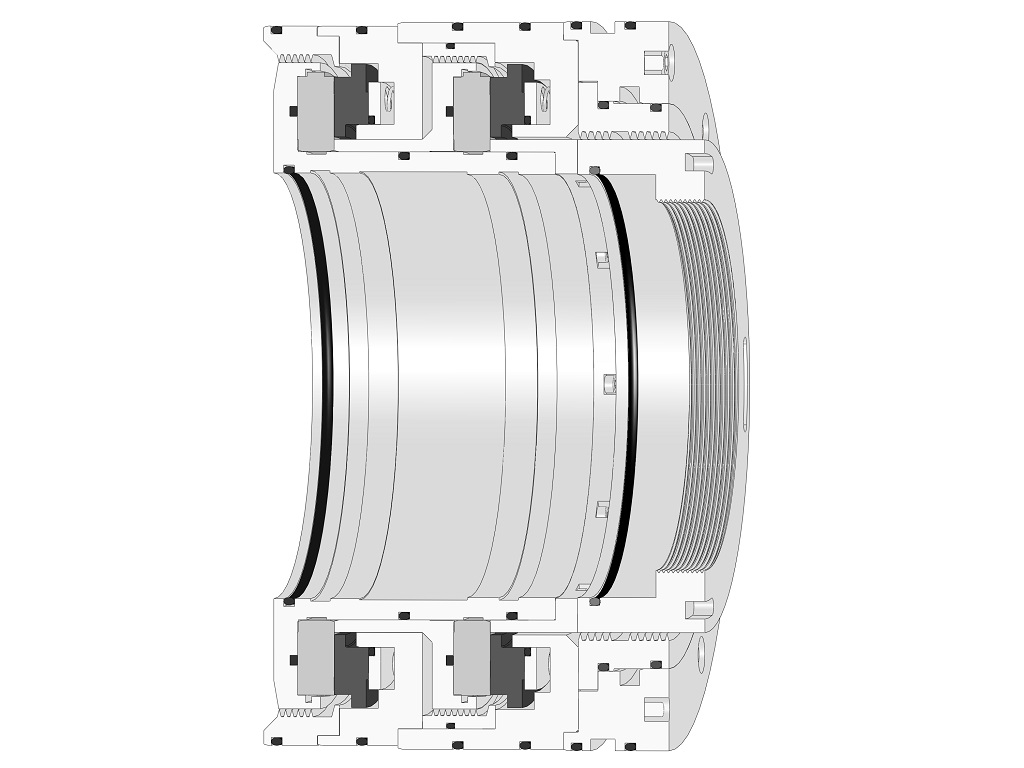

Dry Gas Seal -DG822

Features:

- Tandem Seal

- Unidirectional or bidirectional available

Typical Applications:

Designed in compressors handling various hazardous process media.

Mediums:

For handling hazardous process media:natural gas,cryogenic gases,ethylene/propylene,ammonia,recycle gas and syngas

Performance Capabilities:

Pressure: 0~ 20.0 MPa

Temperature: -100 ~ 260°C

Linear Speed: ≤240 m/s

Material Selection:

Metallic Components: 1Cr13, 304, 316L, 2507, TA2

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC, Graphite

Elastomer Options: FKM, FFKM, EPDM, NBR , OMNISEAL

-

Technical Features:

1.A process-side labyrinth seal is designed to isolate contaminated media, ensuring the mechanical seal operates in a clean environment for extended service life.

2.The primary seal gas(typically process gas)is maintained at a pressure higher than process medium pressure,primary leakage is a mixture of process gas and secondary seal gas, vented to the flare header.

3.An intermediate labyrinth seal and secondary seal gas (buffer gas, typically low-pressure nitrogen) ensure zero process gas leakage to the atmosphere.

4.Secondary leakage (buffer gas + barrier gas mixture) is vented via elevated stack.

5.The atmospheric side incorporates labyrinth seals or segmented carbon rings, preventing process leakage to the environment and protecting the seal faces from bearing oil contamination.

6.The intermediate labyrinth seal prevents process gas leakage. If the primary seal fails, the secondary seal takes over the primary sealing function.

7.The secondary seal gas and separation gas are isolated from the process system.

8.The rotating and stationary rings of the dry gas seal operate in non-contact mode, achieving a long service life.

9.Wide applicability and high safety .

Solution Selection:

Designed for DEREI’s GCS822 dry gas seal support system to ensure stable sealing performance. Customizable configurations available based on user-specific process requirements.