Dry Gas Seal -DG801

Features:

- Single Seal

- Unidirectional or bidirectional available.

Typical Applications:

Widely used in compressors handling non-flammable, non-explosive, and non-hazardous process media.

Mediums:

Designed for use with non-flammable, non-explosive, and non-hazardous process media (liquids and gases) such as air, nitrogen, carbon dioxide (CO2), and steam .

Performance Capabilities:

Pressure: 0~ 15.0 MPa

Temperature: -100 ~ 260°C

Linear Speed: ≤240 m/s

Material Selection:

Metallic Components: 1Cr13, 304, 316L, 2507, TA2

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC, Graphite

Elastomer Options: FKM, FFKM, EPDM, NBR , OMNISEAL

-

Product Description:

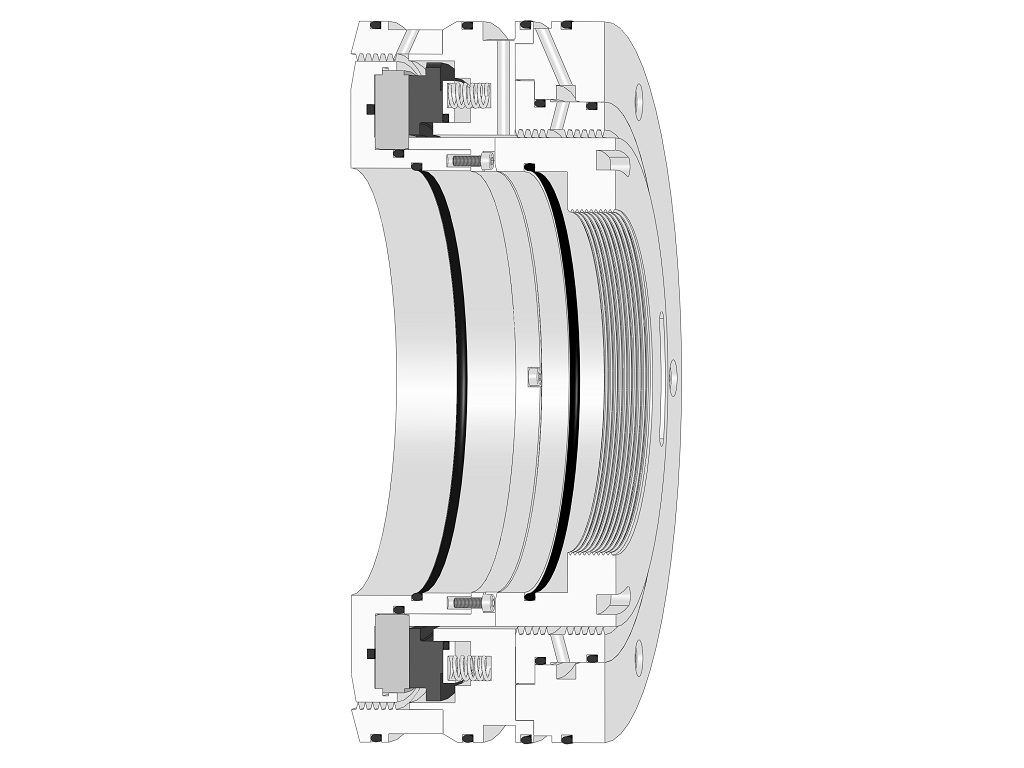

DG801 Dry Gas Seal is designed in accordance with the API617 standard for use in compressor equipment handling non-flammable, non-explosive and non-hazardous process media (liquids or gases). It is rated for a pressure of up to 15 MPa. This dry gas seal assembly includes a sleeve, rotating ring, stationary ring, primary separation seal,auxiliary seals, a compensation mechanism, a seal gland and back-up containment seal .

Technical Features:

1.High-strength, high-performance sealing materials deliver optimal performance.

2.Large-cross-section sealing rings maintain floatability while enhancing sealing performance.

3.The process side features labyrinth or carbon ring separation seals to effectively isolate contaminated media,ensuring the seals operate in a clean environment for extended service life.

4.The seal gas is filtered and pressure-regulated process gas from the dry gas seal support system, ensuring zero process contamination.The dry gas seal support system offers optional drying, pressurization, and heating functions.

5.The atmospheric side incorporates labyrinth seals or segmented carbon rings, preventing process leakage to the environment and protecting the seal faces from bearing oil contamination.

6.Non-contact operation of the dry gas seal ensures extended service life.

Solution Selection:

Designed for DEREI’s GCS801 dry gas seal support system to ensure stable sealing performance. Customization is available based on user application and requirements.