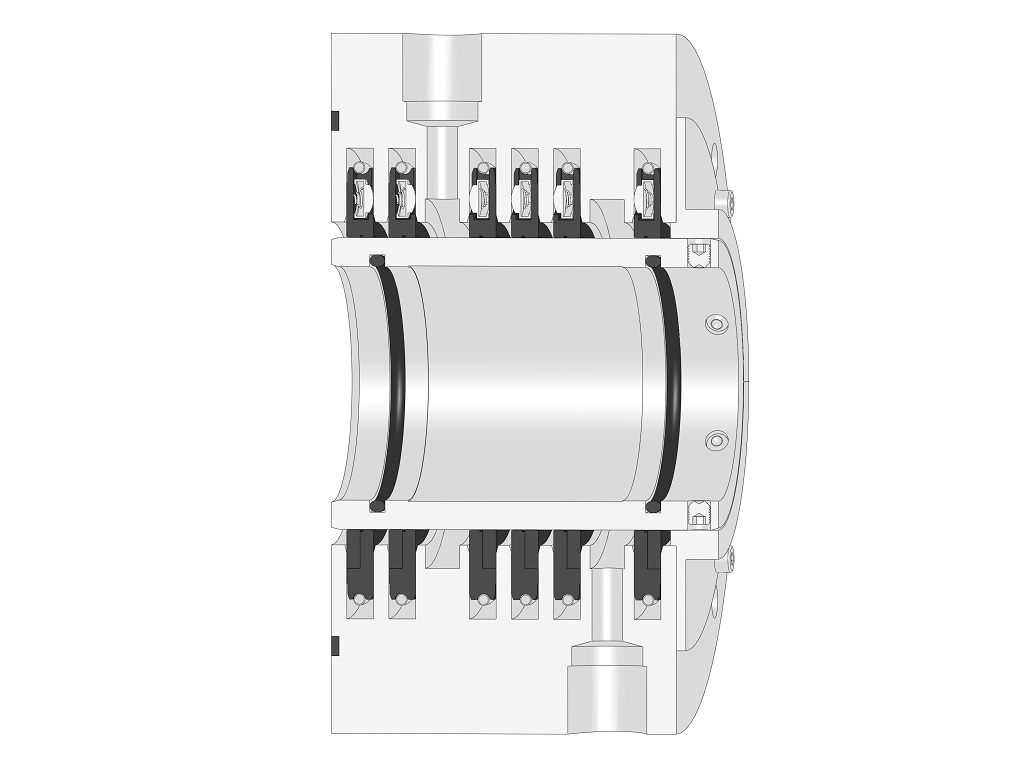

Carbon Floating Ring Seal DC75

Performance Capabilities:

Pressure: ≤0.8 MPa

Temperature: ≤590°C

Linear Speed: ≤60 m/s

Material Selection:

Metallic Components: 1Cr13, 304, 316L, 2507, TA2

Spring: 316L, Hastelloy C-276

Seal Rings: Graphite、PTFE、PEEK

Elastomer Options: FKM、FFKM、EPDM、NBR

Mediums:

Designed for coal gas ,nitrogen, air, steam, and other flammable, explosive gas services.

Typical Applications:

Designed for low & medium-pressure gas transmission equipment:

•Centrifugal fans & blowers

• Roots blowers

• Low-pressure steam fans

• Axial fans

• Centrifugal compressors

• Centrifuges

• Dryers

Optional FDA-compliant materials for:

Food/pharmaceutical grade gas & steam systems

Key Advantages:

Shorter service life than DC71 and DC72, but superior leakage performance compared to DC71.

-

DC75 carbon floating ring seal designed in accordance with API 692, rated for 0.8 MPa. The assembly includes a sleeve, seal rings, seal ring holder ,auxiliary seals, seal gland, mounting plate, and drive mechanisms.

Technical Features:

1. Seal rings running contact.

2.High-strength, high-performance sealing materials .

3.Multi-part seal rings design .

4.Shaft sleeve with advanced wear and corrosion resistance .

5.Split housing design.

6.Drive pin mechanism for high reliability.

7.Cartridge design makes installation and removal easy.

Solution Selection:

Compatible with DC71、DC72、DC73、DC76 seal combinations for different operating conditions.

With DERUI’s GCS74 support system.

Custom configurations available per specific process requirements.