API PLAN 23(MCS23 Forced loop via cooler)

Application

1.Hot hydrocarbons.

2.Hot water services above 80 °C .

3.Boiler feed water.

4.Applications where increasing seal chamber pressure to improve vapor pressure margin is not possible.

Media Characteristics

1.High temperature, clean non-polymerizing fluids.

2.Close to vaporization point.

Features

1.Provides a cool flush to the seal.

2.Improves the product temperature margin to avoid vapor formation.

3.Helps reduce coking.

4.Circulation is maintained by pumping ring.

-

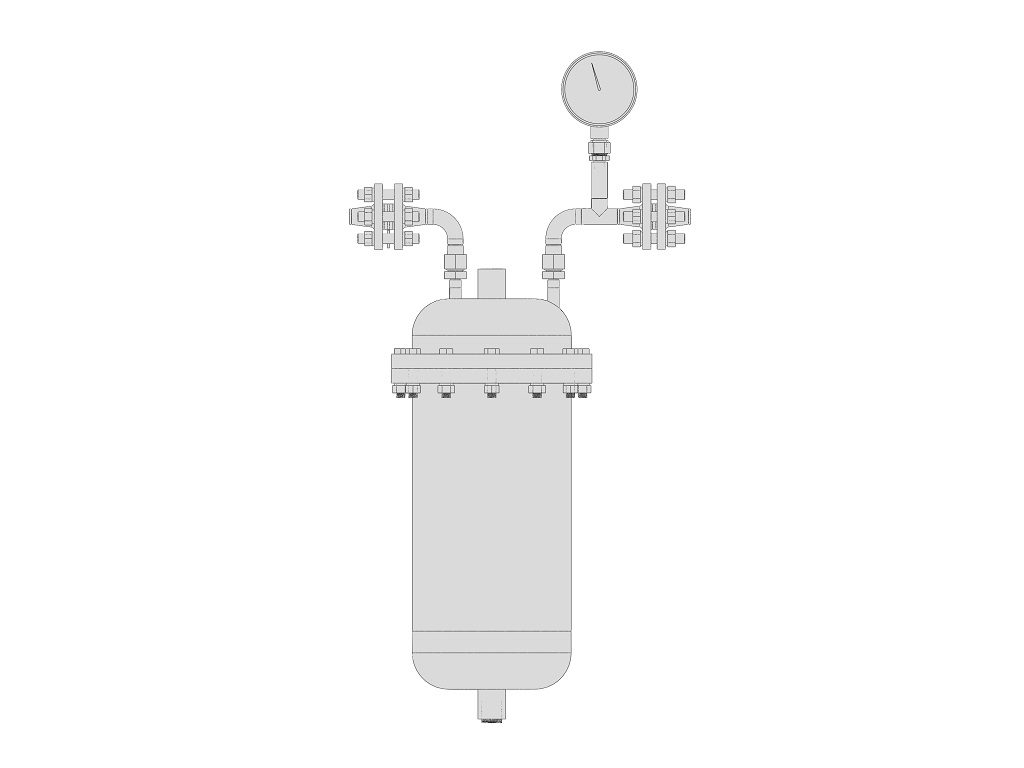

API Plan 23 is a cooling support system for mechanical seals, that effectively improves the seal operating environment. The system mainly consists of connections,cooler,temperature gauge.

Technical Features:

1.The system is suitable for all hot water services, especially boiler feed water and most hydrocarbon applications.

2.Provides cooling and flushing for the mechanical seal. It meets seal temperature requirements, reduces the risk of fluid coking and polymerization, enhances seal lubrication, and improves operating conditions.

3. Recirculation from a circulation device in the seal chamber through a cooler and back into the seal chamber.

4.The cooler only cools the seal flush fluid,ensuring high energy efficiency with minimal thermal load.Optional throttle bushings further reduce heat exchanger demand, significantly extending cooler service life.

5.Removes only the generated seal face heat and the heat soak from the pump area, thus the cooler is smaller and more effective as compared to an equivalent Plan 21.

6.Heat exchanger customized to user’s operating conditions and requirements.