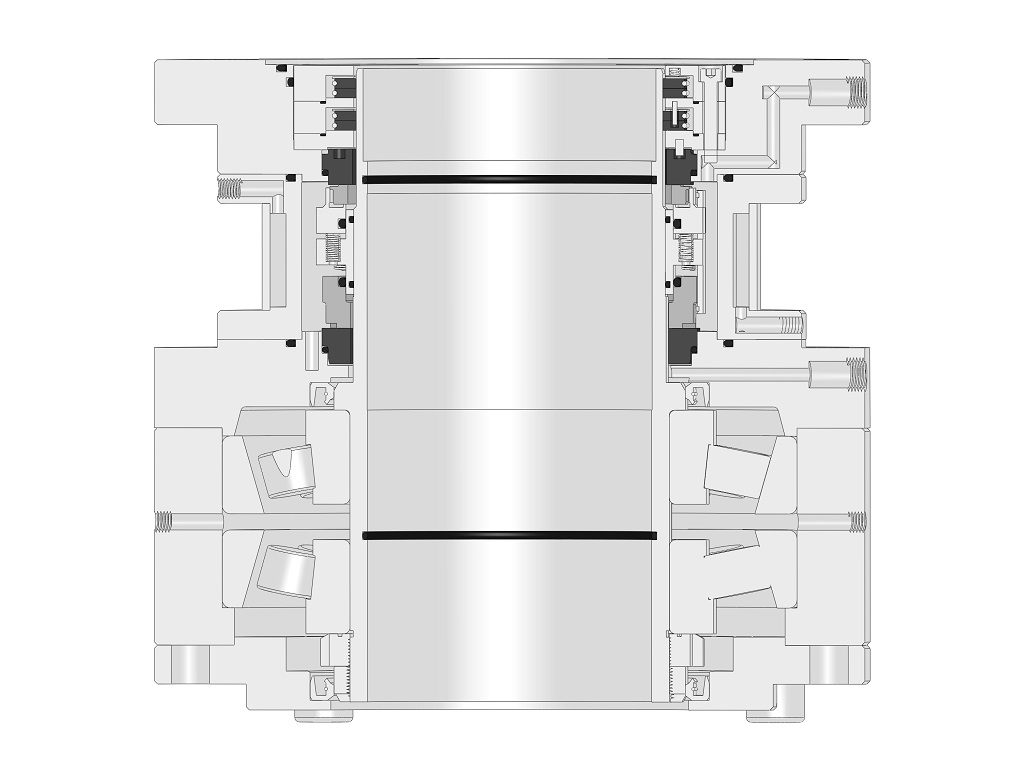

Agitator Seal -DJ233

Features:

- For bottom entry drives

- Dual seal

- Balanced

- Independent of direction of rotation

- Cartridge unit

- With bearing

Typical Applications:

Ideal for bottom-entry agitators in chemical, petrochemical, and energy industries handling liquids, gases, and process media.

Mediums:

Designed for use with toxic, hazardous, flammable, and explosive process media (liquids and gases).

Performance Capabilities:

Pressure: 0~ 4.0 MPa

Temperature: -20 ~260°C

Linear Speed: ≤15 m/s

Material Selection:

Metallic Components: 1Cr13, 304, 316L, 2205、2507、904L、TA2

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC

Elastomer Options: FKM, FFKM, EPDM, NBR

-

DJ233 Dual mechanical seal for bottom-entry agitator is designed in accordance with the API 682 standard for use in agitator handling toxic, hazardous, flammable, or explosive process media (liquids or gases). It is rated for a pressure of up to 4 MPa. It assembly includes sleeve, rotating ring, stationary ring, auxiliary seals, flexible element, seal gland ,bearing and drive mechanism.

Technical Features:

1.Dual mechanical seal with back-to-back arrangement.

2.High-strength, high-performance sealing materials deliver optimal performance.

3. Carbon Ring Barrier Seal – Effectively isolates particulate media from seal faces, extending seal service life.

4.Balanced design with optimized face pressure to minimize heat generation.

5.Bearing-Integrated design for enhanced operational precision.

6.Multi-spring design.

7.Large-cross-section sealing rings maintain floatability while enhancing sealing performance.

8.The highly reliable drive design effectively prevents slippage even on high-hardness shafts.

Solution Selection:

Flush plans Plan 53C or Plan 54.