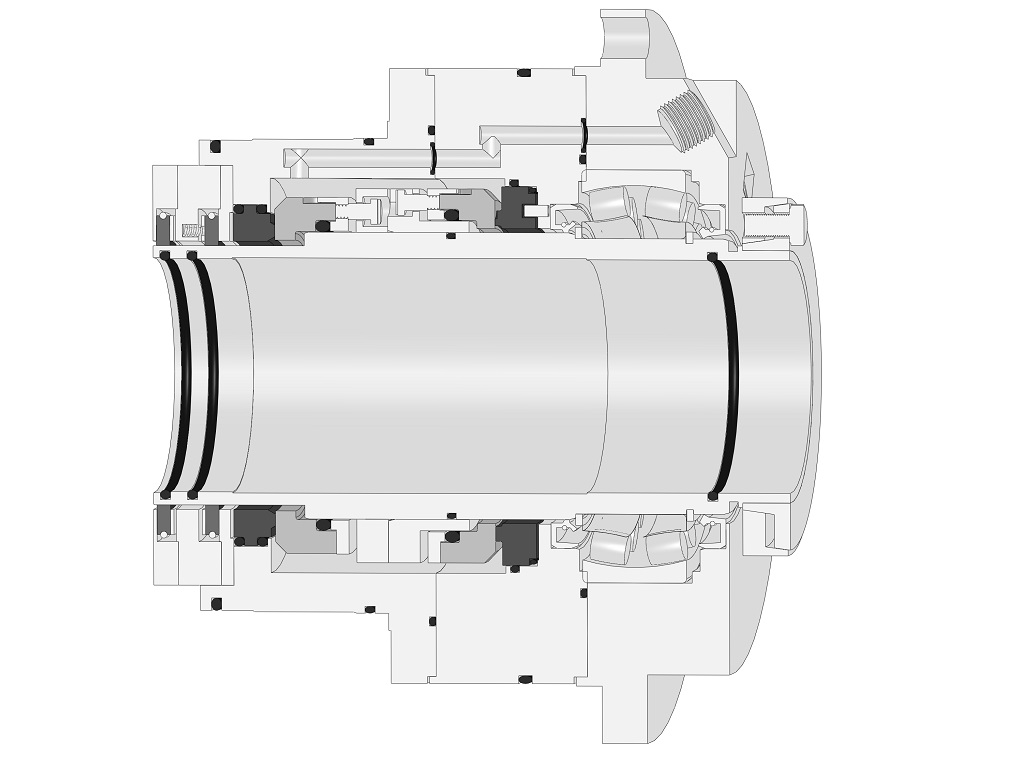

Agitator Seal -DJ231

Features:

- For side entry drives

- Dual seal

- Balanced

- Independent of direction of rotation

- Cartridge unit

- Stationary Multiple springs

- With bearing

Typical Applications:

It is suitable for horizontally installed agitators, alkylation reactors, etc.

Mediums:

Compatible with isobutane and acid-based process media.

Performance Capabilities:

Pressure: 0~ 4.0 MPa

Temperature: -20 ~260°C

Linear Speed: 0~15 m/s

Material Selection:

Metallic Components: High-performance alloy

Spring: Hastelloy C-276

Seal Rings: SSiC

Elastomer Options: FFKM, Aflas、FKM

-

Product Description:

DJ231 dual mechanical seal is designed in accordance with API 682 for agitator applications . It is rated for a pressure of up to 4.0 MPa. This mechanical seal assembly includes sleeve, rotating ring, stationary ring,auxiliary seals, flexible element, seal gland,bearing and a drive mechanism.

Technical Features:

1.High-strength, high-performance sealing materials deliver optimal performance.

2.The special design of the barrier on the medium side completely prevents particulate media from entering the seal face, significantly enhancing the service life of the seal.

3.Anti-misalignment clamping design secures seal rings.

4.Integrated bearing design: Enhances load capacity, controls shaft movement, and prevents seizure and overload due to reactor misalignment.

5.Special treatment of the sleeve for high wear and corrosion resistance effectively prevents leakage caused by media corrosion of the seal position.

6.The highly reliable drive design effectively prevents slippage even on high-hardness shafts.

Solution Selection:

Commonly uses Plan 54 lubrication system to provide cooling and lubrication for seals.