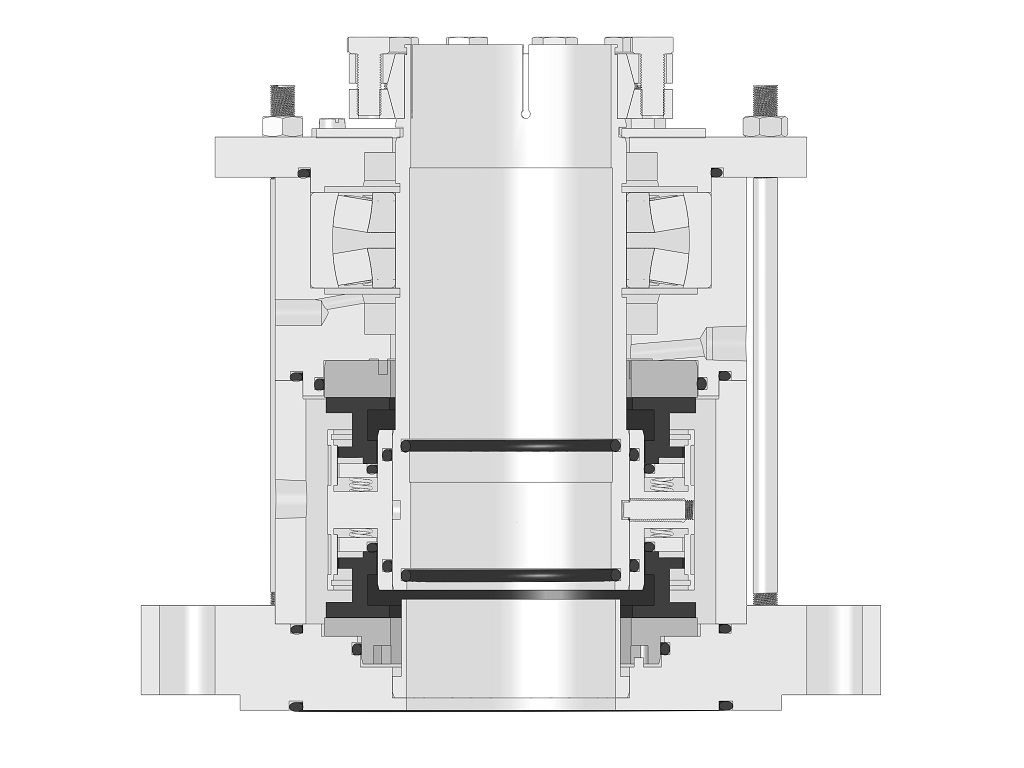

Agitator Seal -DG21D

Features:

- For top entry drives

- Dual seal

- Unidirectional or bidirectional capability

- Cartridge unit

- With bearing

Typical Applications:

Widely used in top-entry agitators handling hazardous media across petrochemical, refining, chemical, pharmaceutical, and environmental industries.

Mediums:

Designed for use with toxic, hazardous, flammable, and explosive process media (liquids and gases).

Performance Capabilities:

Pressure: 0~ 2.5 MPa

Temperature: -20 ~260°C

Linear Speed: ≤15 m/s

Material Selection:

Metallic Components: 1Cr13, 304, 316L, 2507, TA2

Spring: 316L, Hastelloy C-276

Seal Rings: SSiC , WC, Graphite

Elastomer Options: FKM, FFKM, EPDM, NBR , OMNISEAL

-

DG21D top-entry dual dry gas seal is designed in accordance with the API 682 standard for use in rotating equipment handling toxic,hazardous, flammable, or explosive process media (liquids or gases). It is rated for a pressure of up to 2.5 MPa. DG21D top-entry dual dry gas seal assembly includes sleeve, rotating ring, stationary ring, auxiliary seals, flexible elements, bearing, seal gland and a drive mechanism.

Technical Features:

1.DG21D top-entryDual dry gas seal features a back-to-back configuration .

2.Bearing-Integrated design for enhanced running accuracy and stability.

3.The seal gas is supplied from an external inert gas source (nitrogen),it does not react with the process medium, ensuring safe and reliable operation.The seal gas pressure shall be maintained above the process pressure, achieves zero process leakage.

4.The highly reliable drive design effectively prevents slippage even on high-hardness shafts.

5.Non-contact operation of the dry gas seal ensures extended service life.

Solution Selection:

Designed for DEREI’s GCS74 dry gas seal support system to ensure stable sealing performance. Customization is available based on user application and requirements.